Lessons learned from the lumber industry are helping a start-up company in Seattle develop a new type of ultrasound imaging device for dentistry.

S-Ray was formed in 2008 to pursue ultrasonography as a 3D alternative to radiographs for dental applications. The company -- which moved to Seattle in 2010 to take advantage of the region's "ultrasound alley," according to CEO Steve Baird -- is working to commercialize technology created by Ken Johnson, now a retired Oregon dentist, and Dan Tingley, a Canadian timber engineer who happened to visit Dr. Johnson's office with a toothache and didn't want to be exposed to radiation.

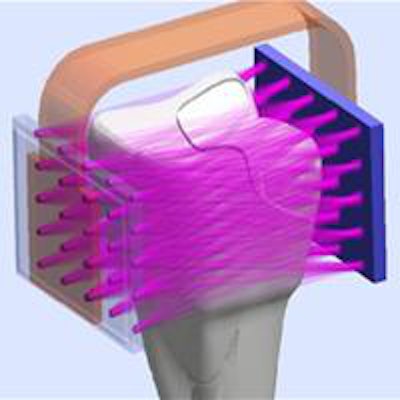

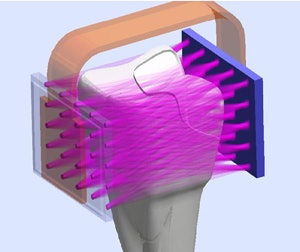

Unlike medical ultrasound, which relies on pulse-echo technology, the S-Ray device produces 3D images by generating an ultrasound pulse or sound wave from one transducer that is received by a second transducer -- a technique called "through transmission," Baird explained.

The S-Ray ultrasound device uses a process known as "through transmission," well-known in the world of nondestructive testing. Image courtesy of S-Ray.

The S-Ray ultrasound device uses a process known as "through transmission," well-known in the world of nondestructive testing. Image courtesy of S-Ray.

"With medical ultrasound, you have one set of transducers that send sound into the body and then waits for the bounce back," he said. "That works really well in soft liquid or semiliquid environments. But it doesn't work well when you run into a hard surface, such as the human tooth. So previous attempts to use pulse echo to look inside the tooth didn't work."

Turns out that Tingley had lectured on the use of ultrasound to look inside logs before cutting them to see where the knots were. They had initially tried to use pulse echo, but then looked at putting transducers on each side of the log so that the signals could be sent from one transducer to the other -- through transmission.

Dr. Johnson quickly saw the similarities to dentistry, and in 2003 the two men patented the idea.

"Through transmission has been in use since the 1950s for industrial nondestructive testing," Baird said. "We have done a lot of pioneering work [in this field], but the reality is we didn't have to. All we had to do was look at a tooth the way Boeing looks at a bolt."

On the market in 2014?

S-Ray is now in the process of developing several prototypes and is in the early stages of working with the U.S. Food and Drug Administration (FDA) to gain marketing approval, with an eye toward a commercial launch in mid-2014. In addition to being a nonionizing 3D imaging tool, the S-Ray ultrasound device will feature a full-mouth appliance that can scan an entire arch in one data file, Baird noted.

"Existing digital impression systems use a point-and-click data acquisition style, and each of those point and clicks are done at a different place inside the oral cavity and the images have to be 'stitched together,' " he said, which can affect the overall resolution and accuracy.

“All we had to do was look at a tooth the way Boeing looks at a bolt.”

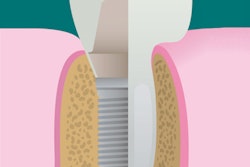

Other advantages of the ultrasound approach include the ability to image all structures -- whether hard or soft tissue -- in the oral cavity with one device and to see all the structures in 3D and create a 3D map of the teeth, added Scott Parker, DDS, executive vice president of S-Ray.

"Up to now we have had to do periodontal probing and charting, which can take 15 minutes," he said. "With this technology, you can get the same information in a single scan and also get information on caries at the same time. So it eliminates the need for full-mouth x-rays and saves the practice a significant amount of time while increasing revenue potential as well."

The technology compares quite well to other imaging modalities in terms of image quality, Dr. Parker added.

"We have the ability to see at a submicron level," he said. "The question is, to what point would we do that? What we really need to determine is just how accurate do we need to be for what we are diagnosing."

For example, if taking a digital impression for an orthodontic aligner, you may need only 80 microns of accuracy, Dr. Parker noted, while 45 microns would be more appropriate if taking a restorative digital impression and 25 microns would be most appropriate for detecting a crack in a tooth, he explained.

Applications abound

The company is focusing on orthodontic treatment planning and progress reports in its initial FDA filings, but the technology could be used for a number of applications in dentistry, according to Baird and Dr. Parker -- including enhancing the relationship between dentists and their lab partners.

"We want to focus on the labs that have existing trusted relationships with the dentists and try and understand what they need to make our technology provide what they need," Baird said. "We can deliver 35 to 50 micron accuracy, but we need to know how they want it delivered. For example, how do they want the prescription? We want to help them understand how to use all this 3D data."

It also has the potential to be a therapeutic device, not just diagnostic, he added.

"We believe we have a platform that can do multiple things on the therapeutic side as well as the diagnostic side," he explained. "With the right material, we can change the structure of that material at the molecular level. So you could use ultrasound to cure restorative materials."

Once S-Ray gains the necessary regulatory clearances, the company hopes to partner with a larger dental firm to handle manufacturing and distribution. The device is expected to sell for $7,500 -- an attractive price point for most practitioners when it comes to digital impressioning and 3D imaging.

"The faster we can figure out everything that ultrasound can do in the mouth, and the faster we can patent it, then the quicker we can hand it off to a bigger company to manufacture and distribute," Baird said.

While they clearly see this is a disruptive technology, S-Ray is not trying to replace anything already on the market, Dr. Parker emphasized.

"Our opinion is that we are an additive technology, another tool in the dentists' belt," he said. "We're not going to replace the x-ray. But if we can deliver everything that it looks like we are able to do, at the price point we are anticipating, I can't imagine any reason a dentist wouldn't want this in their practice."