If your practice has not upgraded to a newer milling unit, what can you do if you want to fabricate screw-retained, provisional implant resin restorations? Researchers tested the idea of using a compact milling unit to manufacture these restorations, and they presented their findings at the 2018 American Association of Dental Research (AADR) meeting in Fort Lauderdale, FL.

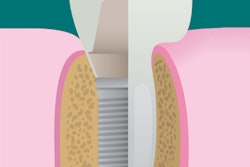

Fabricating a screw-retained, provisional implant resin restoration usually requires an inLab MC XL in-office milling unit (Dentsply Sirona) using Telio CAD A16 blocks (Ivoclar Vivadent). But many practices have not acquired one of these machines and still use compact milling machines.

Researchers wanted to see if they could develop a CAD/CAM protocol to fabricate these restorations using a compact unit. They found they were able to do so using 40-mm Telio CAD for Cerec abutment blocks (Ivoclar Vivadent) instead of the usual blocks.

They described the process and their results in an AADR poster, presented by Guadalupe Garcia Fay, DMD, an assistant professor in the division of prosthodontics at the University of Maryland School of Dentistry in Baltimore.

Successful fabrication

The researchers scanned a TiBase abutment screw (Dentsply Sirona) with a Cerec Bluecam acquisition unit (Dentsply Sirona). They inserted a #14 cone bur onto the left side of the compact milling machine while keeping the standard cylinder-pointed bur on the right side.

They then milled a 40-mm Telio CAD for Cerec abutment block with the compact unit. When milling was finished, they created a perforation for the implant screw to be inserted in the occlusal surface of the milled crown by using a round bur. This differs from the process with A16 blocks, which have machine-milled perforations into which an abutment screw is inserted.

This fabrication method was successfully used to fit provisional crowns in a number of patients, the researchers reported. While they acknowledged that the milled portion of the crown did not fit as precisely as when an A16 block was used, they found good retention between the abutment screw and the milled provisional restorative after cementation.

Using a compact milling unit to fabricate these provisions resin crowns is possible for practices that have not upgraded to a newer milling machine, they concluded.