Extra-narrow implants can fit into spaces that other implants can't, but their indications are limited. Nevertheless, their use has been reported in borderline clinical situations thought to risk implant fracture. To learn more about the capabilities of these implants, researchers examined their biomechanical behavior in the laboratory.

They conducted in vitro tests of 2.9-mm-diameter extra-narrow implants (Facility, Straumann Group) and 3.75-mm-diameter regular size implants (Titamax CM, Straumann), which were manufactured with two different Morse taper systems. The investigators reported their findings in the Journal of Prosthetic Dentistry (June 12, 2019) based on results with 13 specimens placed under six loads.

"From the fatigue test, extra-narrow implants with prosthetic frictional lock connections were compatible with low masticatory effort regions, in agreement with the manufacturer's recommendation," wrote the authors, led by Taís Alves dos Reis, DDS, a doctoral student at the Federal University of Uberlândia School of Dentistry in Brazil.

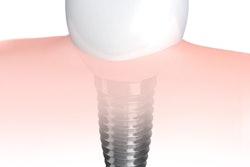

The 2.9-mm-diameter implant in the study uses a pure Morse taper friction lock connection with no internal screw and 5° of angulation of the internal conical portion, which allows it to maintain strength and narrowness, the authors explained. They tested the fatigue limit of this implant with a loading frequency of 15 Hz for 5 x 106 cycles, designed to represent approximately five years of clinical use.

They also used a pullout test, a way to test implant stability and the mechanical interface between implant and bone, to investigate the Morse effect of the 2.9-mm-diameter implant and 3.75-mm-diameter implant, which has 11.5° of angulation of the internal conical portion. During the test, they placed the implants in a polymeric support.

The investigators found that only five specimens did not fail the fatigue test with the frequency and number of cycles used in the study, and the fatigue limit of the extra-narrow implant was 130 Newtons. Additionally, the results of the pullout test were significantly different between the two implant sizes.

Although the researchers noted that the study's findings are limited by its in vitro nature, they concluded that the extra-narrow implant may have performed better in the pullout test due to its design without internal threads and angulation of its internal conical portion.

"Narrow implants with a Morse interface and no internal screws have better retention than the regular-diameter implants," the authors wrote. "The Morse interface without internal screws prevents the narrowing of the walls of the implant, which may be one of the factors that contributes to the clinically acceptable mechanical resistance of narrow implants, according to their clinical indications."