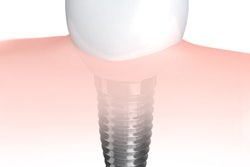

Marginal fit is critical for a restoration's success, but which restoration fabrication method produces a more accurate fit? A new study examined two techniques to find out.

Researchers compared the marginal discrepancies of monolithic zirconia crowns produced by a dental laboratory using a CAD/CAM process and those produced by a milling process. While both crowns fell into the clinically acceptable range, the CAD/CAM crowns had better absolute marginal discrepancy, they reported in BMC Oral Health (June 13, 2019).

"The study revealed that when using a well-known, established CAD/CAM system, zirconia monolithic crowns are a good treatment option as regards marginal fit during tooth restoration," wrote the authors, led by Avi Meirowitz, MDT, and Dr. Yoli Bitterman. Meirowitz is affiliated with the department of oral rehabilitation and Dr. Bitterman is affiliated with the department of orthodontics, both at the Goldschleger School of Dental Medicine at the Tel Aviv University Sackler Faculty of Medicine in Israel.

The researchers wanted to compare the marginal discrepancy and absolute marginal discrepancy of a CAD/CAM process used in a dental laboratory with a milling center for producing monolithic zirconia crowns.

They defined marginal discrepancy as the surface of the cement exposed to the oral environment that can be dissolved, resulting in microleakage, and absolute marginal discrepancy as the under- or overextension of the restoration margins relative to the margins of the preparation. This extension plays a significant role in plaque accumulation, they noted.

The researchers evaluated the marginal fit of 30 zirconia crowns cemented to typodont teeth. They fabricated 15 crowns with a CEREC inLab MC X5 (Dentsply Sirona) from IPS e.max ZirCAD blocks (Ivoclar Vivadent) and the other 15 crowns using a Lava milling center (3M) from Lava Plus Zirconia Blocks (3M). They used a precision saw to section the 30 crowns and measured the marginal and absolute marginal discrepancies.

The absolute marginal discrepancy dimension of the CAD/CAM system was significantly smaller (p < 0.05), the researchers found. Mean absolute marginal discrepancy values for the crowns fabricated by the CEREC inLab were 85 µm compared with 133 µm for the Lava milling center. They found no significant difference between the two systems regarding the marginal discrepancy dimensions (53 µm for the CAD/CAM system and 61 µm for the milling center).

The authors listed several study limitations, including that this was an in vitro study and also that they did not measure the cement thickness in the occlusal area and the seating quality of the crowns. These factors could influence the marginal discrepancy measurements, they noted.

They concluded that the CAD/CAM system demonstrated significantly better marginal fit in terms of the absolute marginal discrepancy, but they noted that both methods were within the clinically acceptable range for marginal discrepancy.